What Bamboo Fiber Wet Wipes Are and Why They Matter Bamboo fiber wet wipes are disposable cleaning wipes made primarily from regenerated bamboo cellulose fibers...

Equipped with professional laboratory, continuous innovation of formula and process.

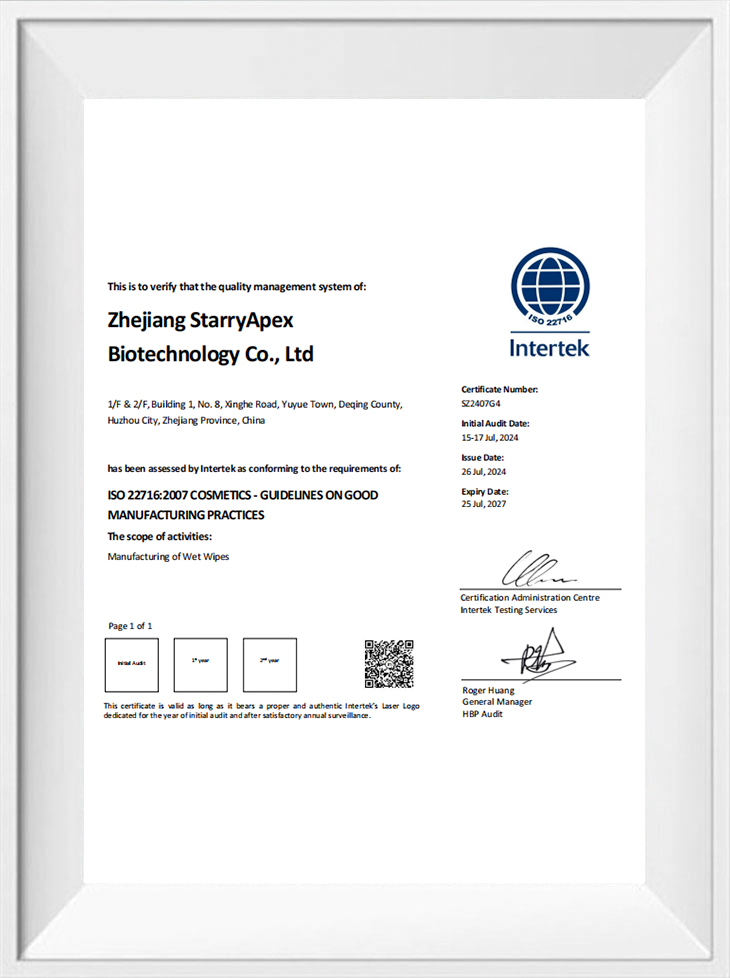

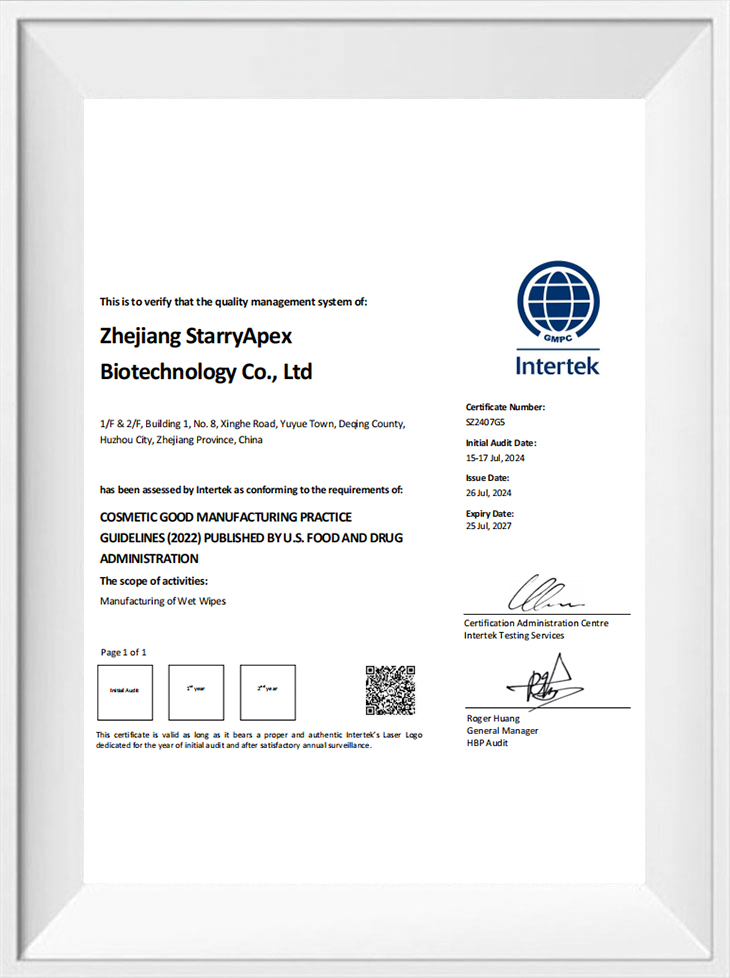

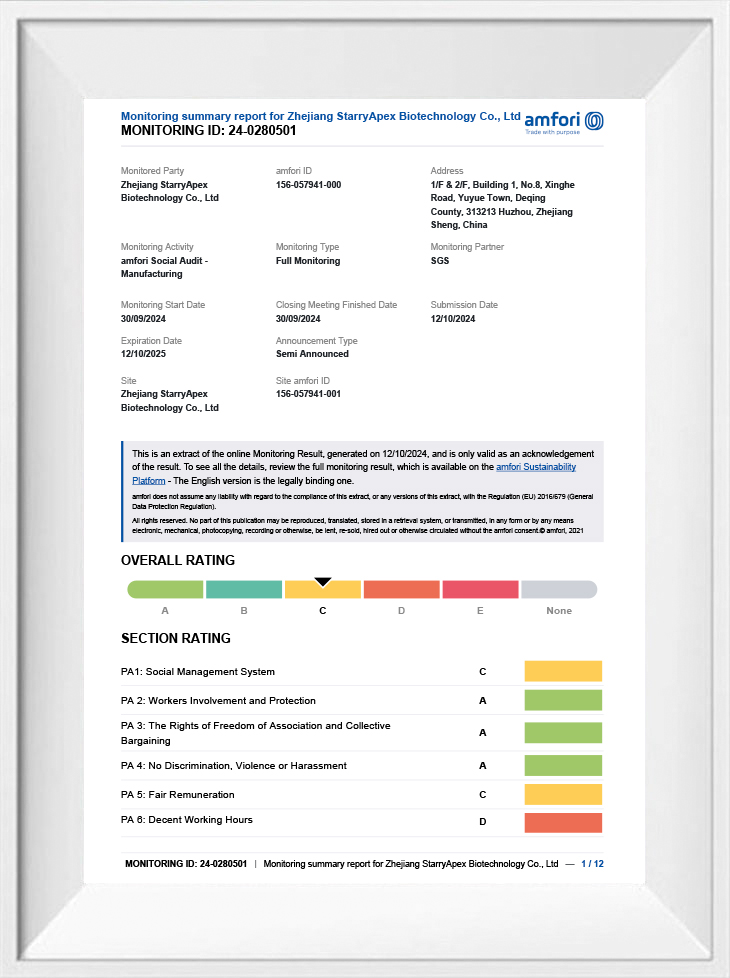

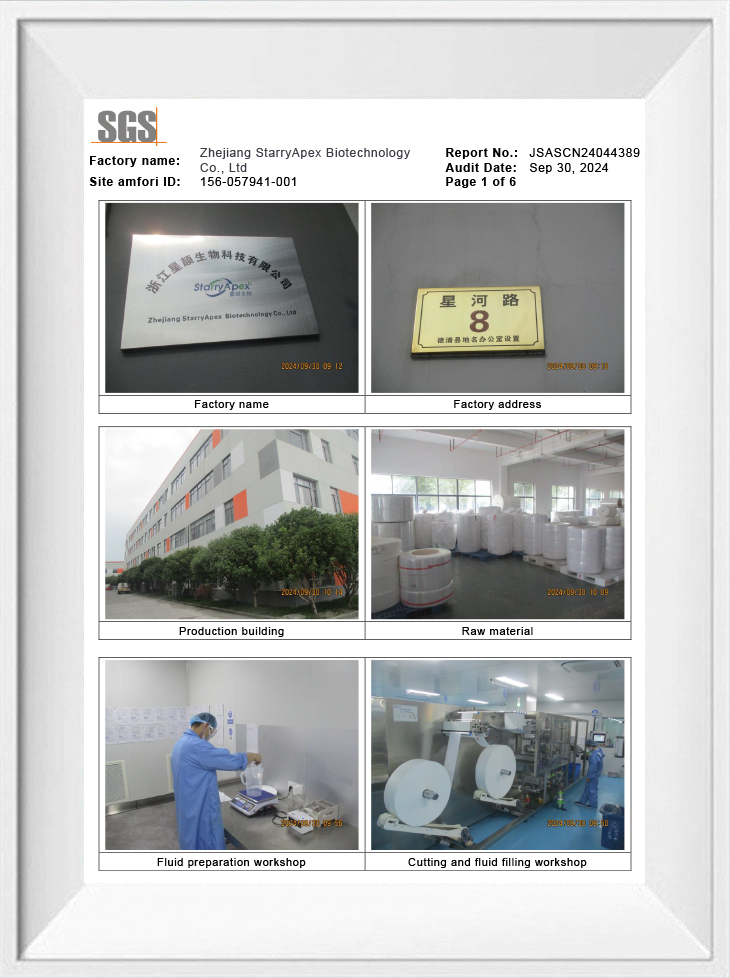

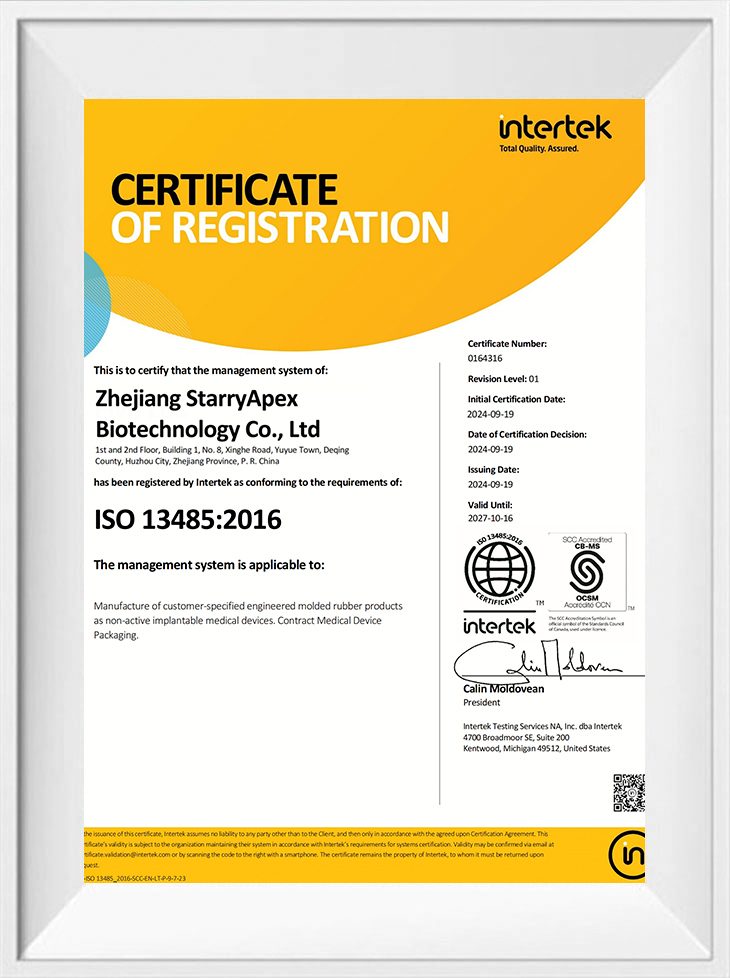

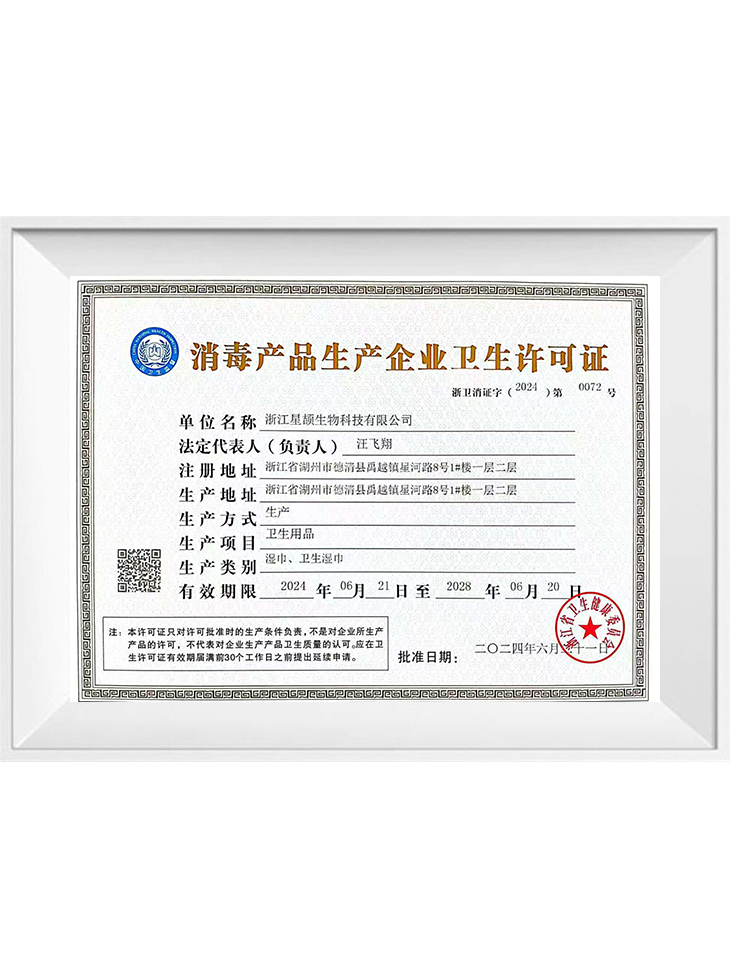

The factory has passed ISO9001, ISO22716, FDA, GMPC, ISO13485, BSCI and other certifications, the use of medical grade clean workshop and EDI ultra-pure water treatment to ensure product safety and no irritation.

Launched degradable non-woven fabrics, pure water formula and other green products, in line with international environmental regulations.

Products are exported to Europe, the United States, the Middle East, Southeast Asia and other countries, serving well-known maternal and child brands/chain stores/medical institutions and other customers, with stable quality and rapid response to win market trust.

-

-

What Are Cooling Wipes and How Do They Work? Cooling wipes are pre-moistened cloths designed to provide instant relief from heat, sweat, or irritation. They oft...

-

Why Kitchen Cleaning Wipes Are Essential for a Hygienic Kitchen Kitchen cleaning wipes are an essential tool for maintaining a clean and safe cooking environmen...

Understanding the Full Supply Chain Behind Cotton Buds and Pads Manufacturing and Export

From the moment raw cotton is harvested in the fields to the final boxed product ready for global shipment, the supply chain of cotton buds and pads reflects both complexity and precision. As a manufacturer deeply involved in each stage, we understand that the journey of these everyday hygiene essentials is shaped by countless technical and quality considerations that buyers often don’t see at first glance. Yet, for B2B partners seeking reliability, consistency, and compliance, understanding this background is vital.

It all begins with the selection of cotton itself. Not all cotton is created equal—fiber length, cleanliness, and moisture content directly influence how well the material performs when transformed into either soft cotton tips for buds or the absorbent sheets used in pads. We source high-grade cotton from certified suppliers, ensuring purity and consistency that meets both cosmetic and medical standards. After ginning and cleaning, the cotton goes through specialized processing to eliminate impurities, align fibers, and prepare it for various product lines. For cotton buds, this involves creating tightly wound tufts that remain firm and lint-free; for pads, it requires controlled layering to optimize water absorption and softness.

The production phase introduces a combination of automation and precise human oversight. Cotton buds are assembled using high-speed machines that affix the cotton to plastic, paper, or wooden sticks. The uniformity of shape and secure adhesion is essential for safe use, especially in sensitive applications like skincare or ear care. Cotton pads, on the other hand, are cut from continuous rolls into different shapes—round, square, or oval—depending on client requirements. At this stage, embossing, edge sealing, and folding can be applied based on market preferences. Each unit is carefully inspected to ensure that the cotton structure remains intact and free from fraying or inconsistencies.

Packaging is more than just wrapping. For cotton buds and pads, packaging plays a critical role in maintaining hygiene, meeting shelf-life expectations, and communicating quality to end users. We offer a range of options—from sterile blister packs for medical-grade swabs to resealable pouches and eco-friendly paper boxes for retail cotton pad products. All packaging is designed with durability and transport efficiency in mind, ensuring the products arrive in perfect condition no matter the destination.

Throughout the entire supply chain, quality control checkpoints are integrated at every major stage. These include microbiological tests, visual inspections, and performance assessments such as absorbency rate, tensile strength, and lint level. Compliance with ISO standards, CE marking, and other international certifications is built into our workflow, which allows buyers to confidently distribute our cotton buds and pads across regulated markets. Our experience as an exporter means we are also well-versed in handling documentation, customs clearance, and adapting to import regulations across regions like the EU, Middle East, and Southeast Asia.

Logistics planning completes the cycle. We understand that lead time, MOQ flexibility, and dependable shipping partners can make or break a B2B relationship. That’s why we work closely with clients to forecast demand, maintain buffer stock for recurring orders, and optimize packaging formats for container efficiency. Whether you’re sourcing for hospital supply chains, beauty product lines, or retail distribution, our goal is to streamline your procurement process while delivering consistent quality.

At every step, we combine technical know-how with real-world experience to offer more than just a product—we offer a supply partnership. Cotton buds and pads may seem simple on the surface, but what sets a good supplier apart is control over every link in the chain. We invite potential clients to explore how working directly with a dedicated manufacturer can add stability, transparency, and long-term value to your business.

English

English 日本語

日本語 Español

Español عربى

عربى Deutsch

Deutsch Français

Français Baby Wipes

Baby Wipes Industrial & Automotive Wipes

Industrial & Automotive Wipes Biodegradable Wipes

Biodegradable Wipes Cotton Buds and Pads

Cotton Buds and Pads