What Bamboo Fiber Wet Wipes Are and Why They Matter Bamboo fiber wet wipes are disposable cleaning wipes made primarily from regenerated bamboo cellulose fibers...

Equipped with professional laboratory, continuous innovation of formula and process.

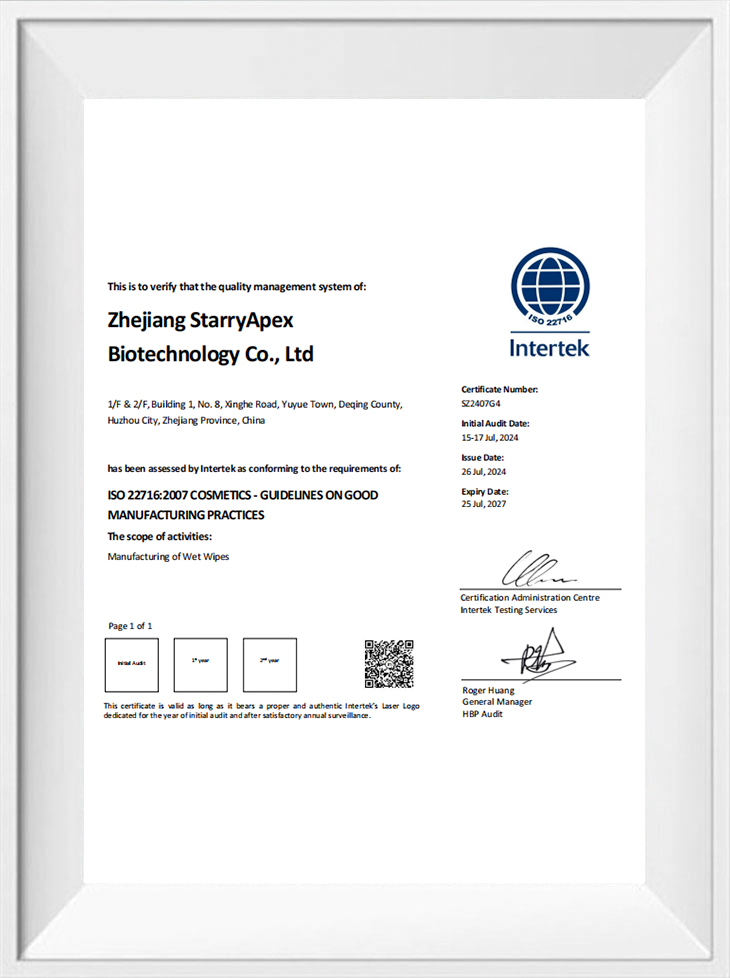

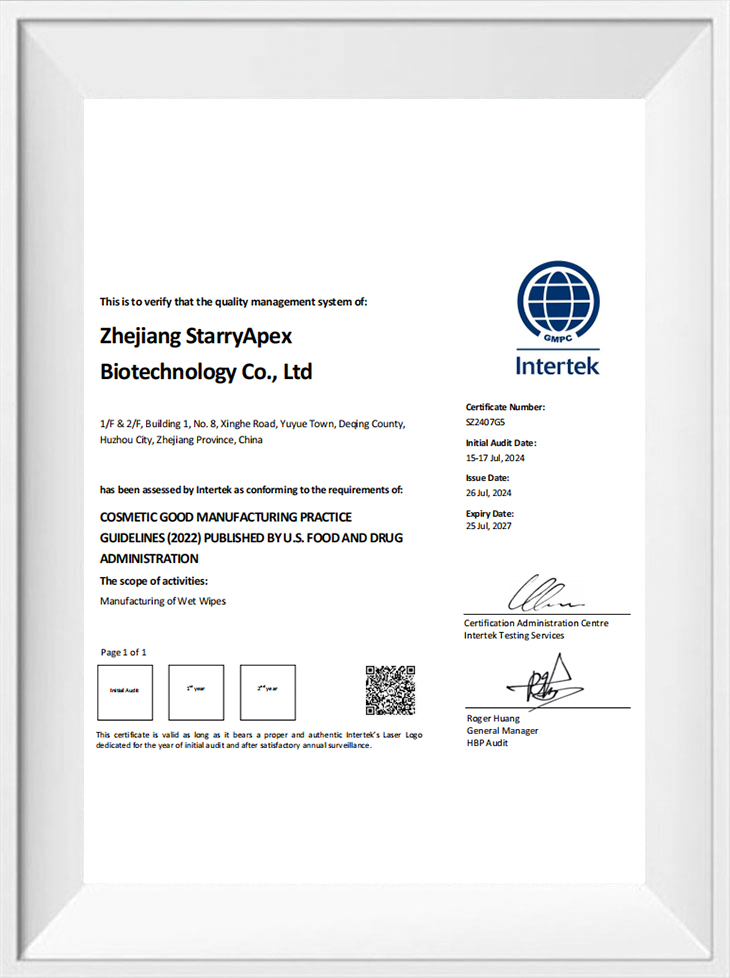

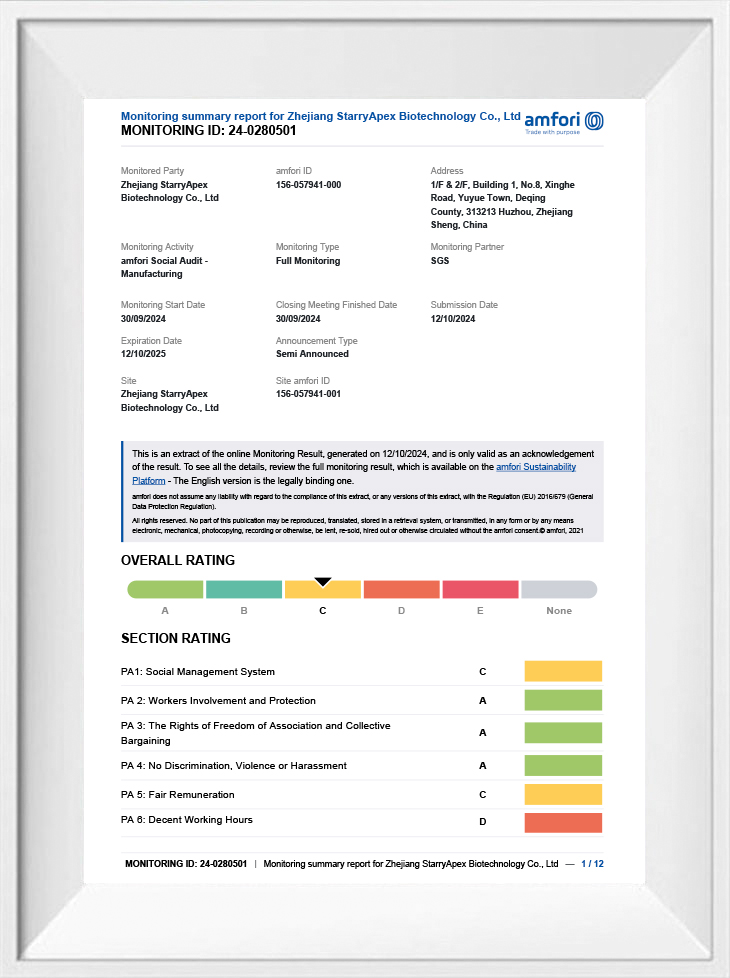

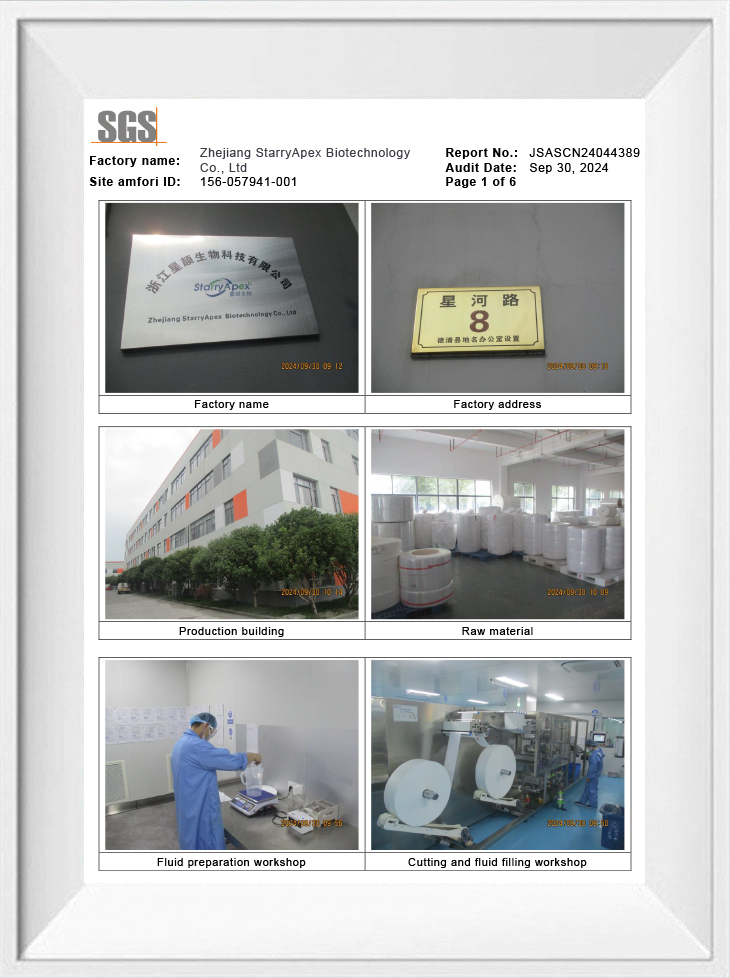

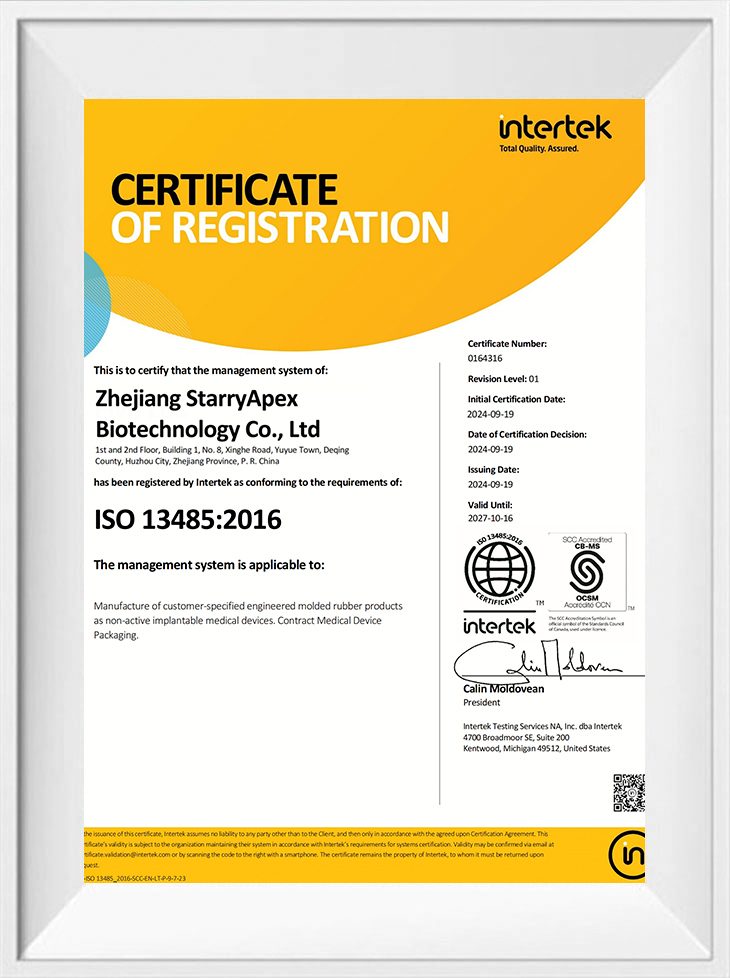

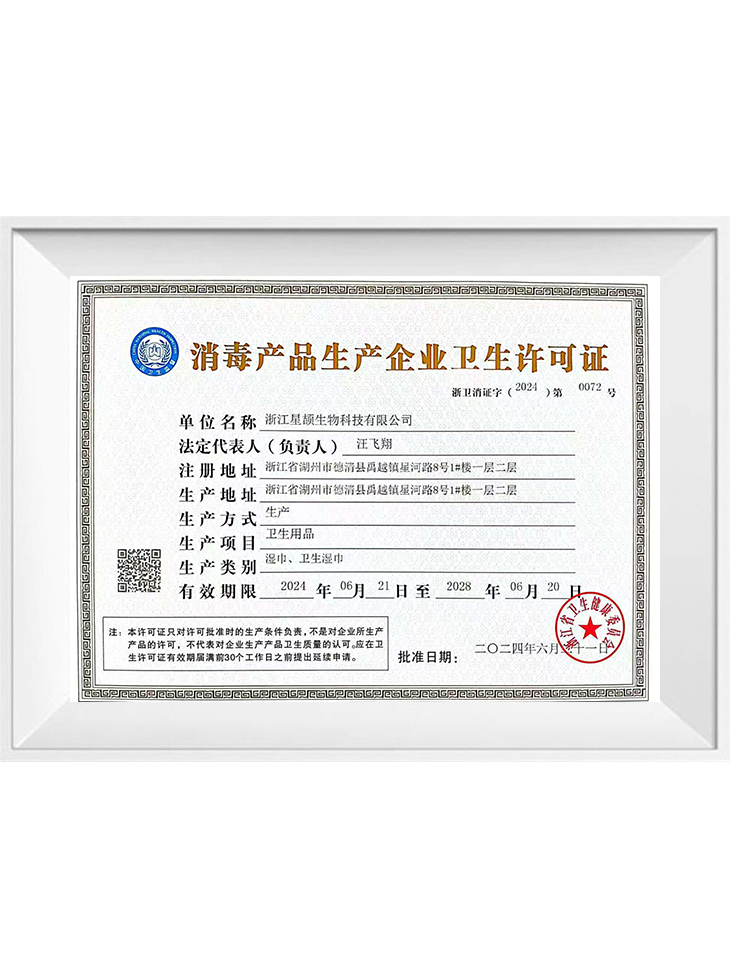

The factory has passed ISO9001, ISO22716, FDA, GMPC, ISO13485, BSCI and other certifications, the use of medical grade clean workshop and EDI ultra-pure water treatment to ensure product safety and no irritation.

Launched degradable non-woven fabrics, pure water formula and other green products, in line with international environmental regulations.

Products are exported to Europe, the United States, the Middle East, Southeast Asia and other countries, serving well-known maternal and child brands/chain stores/medical institutions and other customers, with stable quality and rapid response to win market trust.

-

-

What Are Cooling Wipes and How Do They Work? Cooling wipes are pre-moistened cloths designed to provide instant relief from heat, sweat, or irritation. They oft...

-

Why Kitchen Cleaning Wipes Are Essential for a Hygienic Kitchen Kitchen cleaning wipes are an essential tool for maintaining a clean and safe cooking environmen...

Understanding the Science Behind Biodegradable Wipes: How Eco Friendly Wet Wipes Are Made and Break Down Naturally

In today’s market, the demand for eco friendly wet wipes is rapidly increasing as more businesses seek sustainable alternatives to conventional disposable products. At the heart of this shift lies the fascinating science behind biodegradable wipes, a product line that combines environmental responsibility with effective cleaning performance. Unlike traditional wipes made from synthetic fibers, biodegradable wipes are crafted from natural or specially engineered materials such as cellulose fibers derived from wood pulp or polylactic acid (PLA) sourced from renewable resources like corn starch. These materials not only offer a soft and strong texture but also set the stage for an eco-friendly disposal cycle.

The manufacturing process of biodegradable wipes involves a careful balance of material selection and production techniques to ensure the final product meets performance standards while remaining fully compostable or biodegradable under the right conditions. Cellulose fibers, for example, are processed to maintain absorbency and durability, while additives used are chosen to be non-toxic and skin-friendly. In the case of PLA, this biopolymer is synthesized through fermentation processes that convert plant sugars into lactic acid, which is then polymerized into a fiber that mimics synthetic materials but decomposes much more readily.

What makes biodegradable wipes truly unique is their ability to break down into harmless substances when exposed to natural environmental factors. This biodegradation is driven by microorganisms such as bacteria and fungi, which consume the fibers as a nutrient source. The process depends heavily on conditions like moisture, temperature, and oxygen availability—factors commonly found in industrial composting facilities but sometimes achievable in natural soil environments. Over weeks to months, the wipes gradually disintegrate into water, carbon dioxide, and biomass, leaving minimal ecological footprint compared to synthetic wipes that can persist for decades in landfills.

From a technical perspective, the biodegradability of eco friendly wet wipes is tested against rigorous industry standards to ensure they meet criteria for compostability and environmental safety. These tests simulate real-world conditions to measure the rate and completeness of degradation, as well as the absence of toxic residues. For B2B buyers looking to offer responsible products to their customers, understanding these technical aspects is crucial for verifying claims and maintaining supply chain transparency. As a manufacturer deeply invested in sustainability, we emphasize these certifications to guarantee that every biodegradable wipe leaving our production line delivers on both quality and environmental promise.

One of the biggest challenges in this field is optimizing the balance between biodegradability and product performance. Wipes must be strong enough to withstand usage without tearing, highly absorbent to handle various cleaning tasks, and gentle on the skin—all while maintaining their ability to break down efficiently after disposal. Advances in material science, including the blending of natural fibers with bio-based polymers and the use of safe enzymatic treatments, have enabled the development of wipes that satisfy these demanding requirements, making them an increasingly viable alternative for multiple industries.

Choosing biodegradable wipes is not just about switching to an eco-conscious product; it is about embracing a smarter solution that respects both consumer needs and environmental limits. As manufacturers committed to quality and innovation, we continuously invest in research and development to refine the science of biodegradable wipes, ensuring our clients receive effective, reliable, and truly sustainable products. By understanding the underlying science, businesses can confidently promote their use of eco-friendly wet wipes as part of a broader commitment to sustainability, appealing to conscientious customers while contributing positively to the planet.

Biodegradable wipes represent a sophisticated convergence of natural materials, biological processes, and cutting-edge technology. Their ability to perform like traditional wipes yet degrade naturally is a testament to ongoing innovation in eco-friendly product development. For companies looking to align with green initiatives without compromising on product excellence, investing in biodegradable wipes offers a practical and forward-thinking choice that benefits both users and the environment.

English

English 日本語

日本語 Español

Español عربى

عربى Deutsch

Deutsch Français

Français Baby Wipes

Baby Wipes Industrial & Automotive Wipes

Industrial & Automotive Wipes Biodegradable Wipes

Biodegradable Wipes Cotton Buds and Pads

Cotton Buds and Pads